|

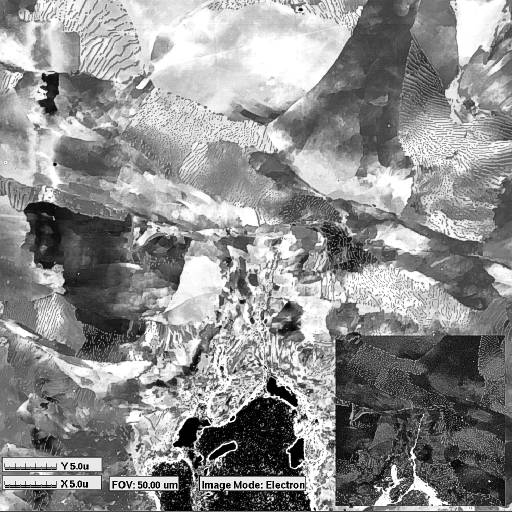

Comparative FIB images of a crack in a pipeline steel are shown, acquired using secondary electron and secondary ion signals.

The ion image (inset) highlights the corrosion product in the crack

itself, while the electron image shows the microstructural features within the plastic zone around the crack tip. This

sample was metallographically polished prior to FIB imaging.

FIB secondary ion images are particularly sensitive to the presence of oxides and carbides in metallic systems due to

the effect these elements have on the secondary ion yield of the metal. The oxygen or carbon "enhanced yield" can

cause order-of-magnitude or more increases in the brightness of a region containing metal oxides or carbides,

creating a chemical contrast effect that makes FIB SII an ideal technique for identifying corrosion or grain boundary

segregation without resorting to chemical etching. Eliminating the need to use chemical etching is significant as many

etchants contain elements that are also expected to be

found in the native corrosion products. Etching frequently contaminates the sample to a depth of several micrometers

into precipitates or porous grain boundaries. FIB SII and SEI imaging combined with careful metallographic

polishing techniques that minimize mechanical deformation introduced during preparation prior to FIB work permits

the use of FIB micromachining to produce TEM specimens with virtually a one-to-one correspondence between the

TEM specimen and the FIB imaged region - without concern that the chemical analysis to be performed in the TEM

will be compromised by chemicals in a conventional etchant.

|